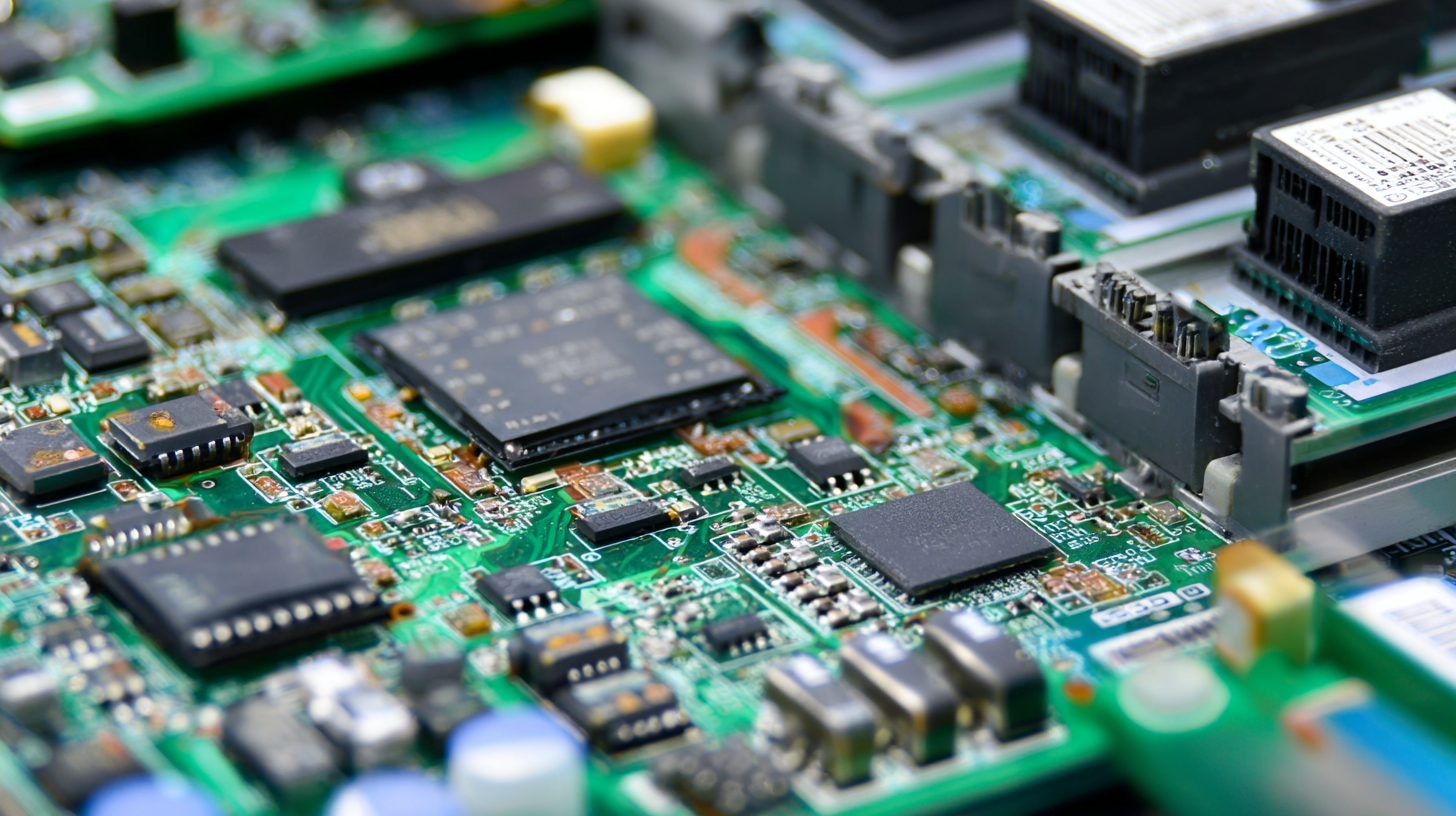

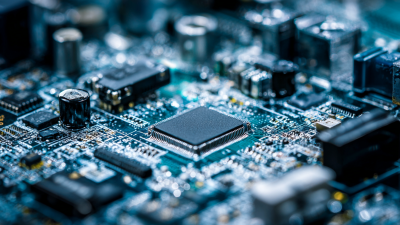

WORLD electronics offers a complete line of electronic circuit board manufacturing and assembly services, as well as advanced manufacturing services. Our commitment to quality and service is second to no supplier.

Learn MoreOur team of engineers assists you in the development of new designs to optimize quality manufacturability (DFM) and testability, resulting in cost minimization and reduced product development time.

Learn MoreOur flexible manufacturing floor layout and highly trained staff allow for Quick Set-up and Tear Down of small volume prototype runs. This combination grants our customers the benefit of turning new designs quickly and accurately.

Learn MoreWORLD electronics is dedicated to quality. This quality is what underpins our commitment to thorough testing. Our engineers can develop a set of tests that ensure reliability and high performance in all products.

Learn MoreSupply chain management has crossed over from being a narrow management function to being a key operational function.

Learn More

In the rapidly evolving electronics landscape, optimizing PCB assembly board production has become paramount for manufacturers aiming to achieve maximum efficiency and quality. According to a report by IPC, the global printed circuit board market is projected to reach $81.78 billion by 2026, underscoring the critical need for manufacturers to refine their processes to remain competitive.

Moreover, studies indicate that inefficiencies in assembly can result in a staggering 20-30% increase in production costs, highlighting the importance of strategic improvements. By implementing best practices in design for manufacturability, investing in advanced automation technologies, and prioritizing quality assurance measures, companies can significantly enhance their PCB assembly board production.

This article provides insights into the most effective strategies that not only streamline operations but also ensure a high level of product reliability and performance.

To streamline PCB assembly processes and minimize wastage, several key strategies can be employed.

First, implementing lean manufacturing principles can significantly reduce excess materials and improve workflow efficiency. By mapping out the entire assembly process, manufacturers can identify bottlenecks and areas where waste occurs, allowing for the elimination of unnecessary steps. This approach not only helps in optimizing resource utilization but also minimizes production times, thereby increasing overall efficiency.

Another crucial aspect is the integration of automation technology within the assembly line. Automated systems can enhance precision in component placement and soldering, leading to a reduction in defects and material waste. Additionally, adopting just-in-time inventory practices ensures that materials are used as needed, preventing overstocking and minimizing the likelihood of obsolete components.

By fostering a culture of continuous improvement and staying updated with industry advancements, PCB manufacturers can maintain high standards of quality while effectively managing costs and reducing waste.

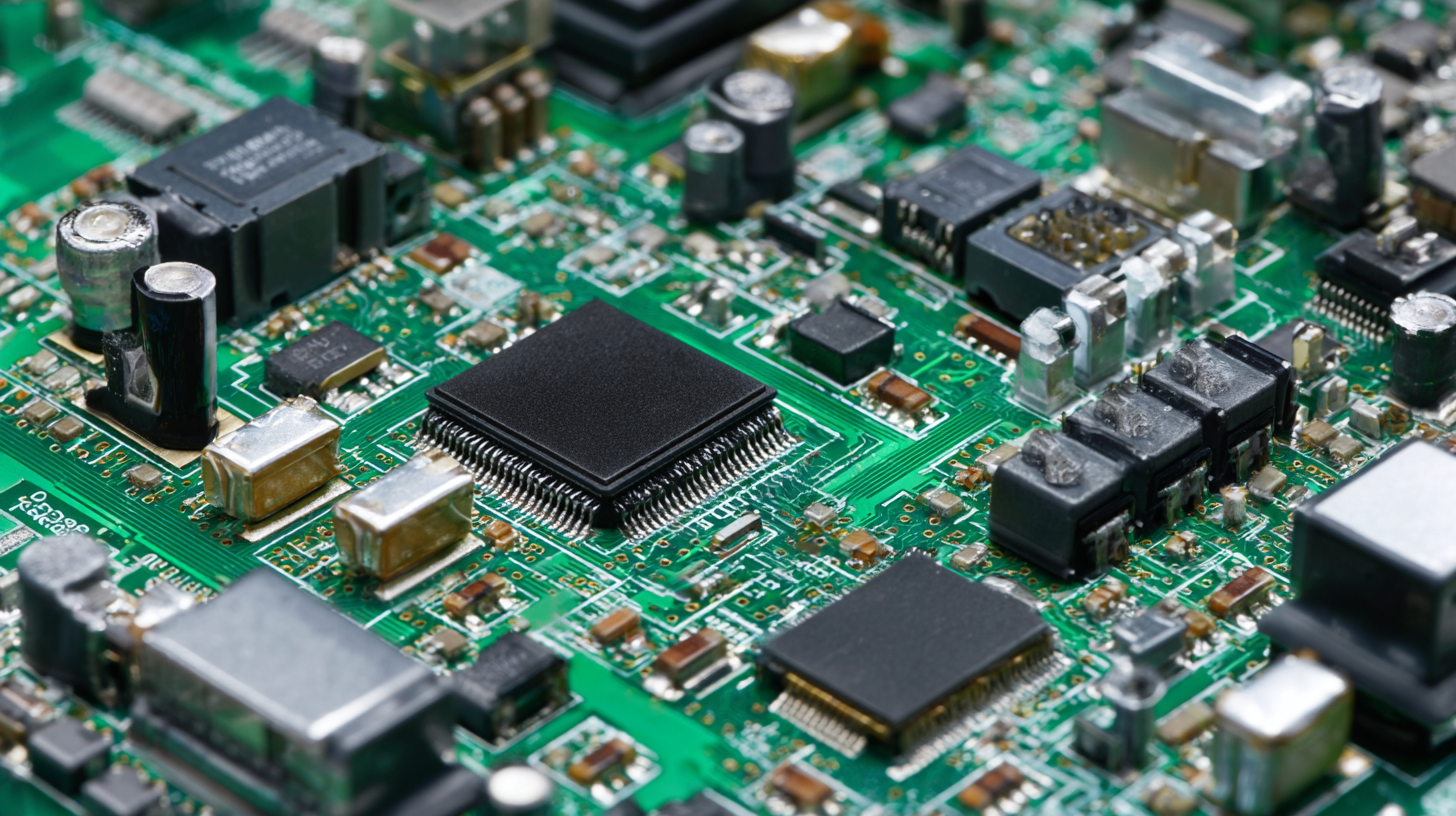

Selecting high-quality components is crucial for ensuring optimal performance in PCB assembly. The effectiveness and reliability of a PCB often hinge on the components chosen during the design phase. High-quality components can significantly reduce failure rates and enhance the overall functionality of the electronic devices. Therefore, it is essential to prioritize reputable suppliers known for their rigorous quality control processes and reliable products.

**Tips for Component Selection:**

When selecting components, always review datasheets thoroughly. These documents provide essential information regarding electrical specifications, recommended operating conditions, and longevity data. Additionally, consider sourcing components that have certifications such as ISO or RoHS, as these indicate compliance with international quality and safety standards.

Another important aspect is to assess the compatibility of components with your PCB design. Utilizing simulation tools to predict how various components will interact within the circuit can help identify potential issues before production, ensuring each aspect of the board performs optimally. By doing so, you can minimize design changes later in the process, leading to increased efficiency and reduced costs.

| Component Type | Quality Rating | Lead Time (Weeks) | Cost per Unit ($) | Recommended for High-Volume Production |

|---|---|---|---|---|

| Resistors | A | 2 | 0.05 | Yes |

| Capacitors | B | 3 | 0.10 | Yes |

| ICs | A+ | 4 | 0.50 | Yes |

| Connectors | B+ | 5 | 0.25 | No |

| Microcontrollers | A | 6 | 1.00 | Yes |

In the ever-evolving landscape of PCB assembly, leveraging automation technologies has become essential for enhancing efficiency and ensuring higher product quality. According to a report by IPC, automating PCB assembly lines can improve production speed by up to 30%, thus significantly reducing time-to-market. This is particularly crucial as the demand for faster, more reliable electronic components continues to rise.

Implementing automation not only streamlines processes but also minimizes human error, which is a common challenge in manual assembly. The latest advancements in robotics and AI-driven inspection systems help in identifying defects early in the production process, leading to a 20% reduction in rework costs, as highlighted by a study from Grand View Research. By incorporating these technologies, manufacturers can maintain quality standards while scaling their operations effectively.

Tips:

1. Invest in flexible automation solutions that can be quickly adapted to different product lines, allowing for faster setup times.

2. Utilize real-time data analytics to monitor production performance, enabling quicker adjustments that enhance efficiency.

3. Train staff on the latest automation technologies to ensure seamless integration into current workflows, fostering a culture of continuous improvement.

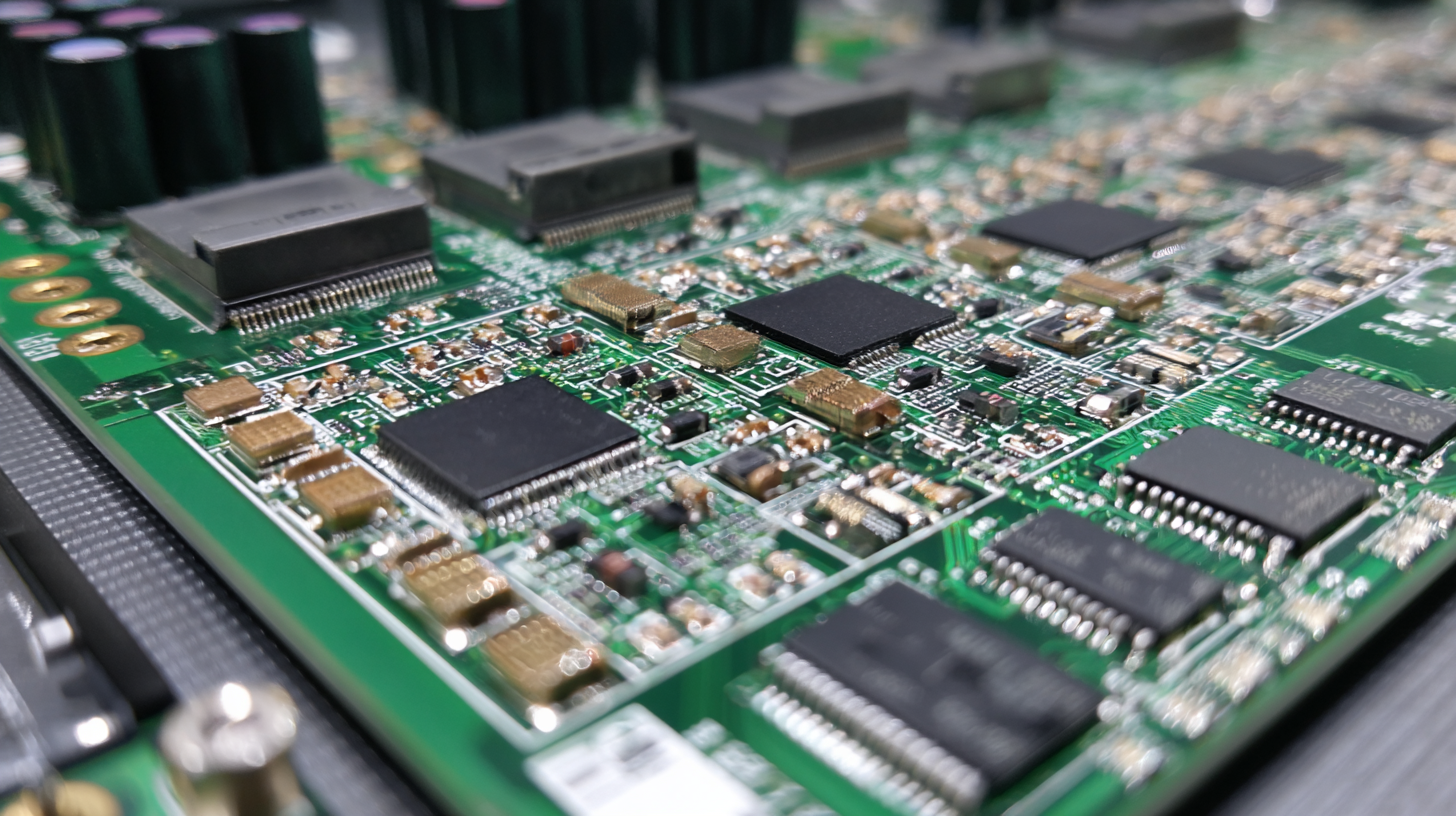

Ensuring the quality and reliability of printed circuit boards (PCBs) is crucial for the overall success of electronic manufacturing. Implementing effective testing procedures can dramatically reduce failure rates and enhance product performance. According to a report from the IPC (Association Connecting Electronics Industries), approximately 20% of all PCBs are returned due to reliability issues, highlighting the need for rigorous testing protocols. By integrating Automated Optical Inspection (AOI) and X-ray inspection systems into the assembly line, manufacturers can identify defects early in the production process, leading to a significant decrease in rework costs and improved product lifespan.

Ensuring the quality and reliability of printed circuit boards (PCBs) is crucial for the overall success of electronic manufacturing. Implementing effective testing procedures can dramatically reduce failure rates and enhance product performance. According to a report from the IPC (Association Connecting Electronics Industries), approximately 20% of all PCBs are returned due to reliability issues, highlighting the need for rigorous testing protocols. By integrating Automated Optical Inspection (AOI) and X-ray inspection systems into the assembly line, manufacturers can identify defects early in the production process, leading to a significant decrease in rework costs and improved product lifespan.

Furthermore, the use of advanced testing methodologies, such as Design for Testability (DFT), is becoming increasingly important. A study by Edn Network indicates that up to 90% of electronic design engineers are incorporating DFT practices in their workflows, allowing for easier debugging and reliability assessments. By utilizing these practices, companies can ensure that their PCBs meet high standards of quality and can withstand the demands of real-world applications. Implementing a systematic approach to testing not only improves efficiency in production but also results in a higher level of consumer trust in the final product.

In the ever-evolving landscape of PCB assembly, leveraging data analytics has emerged as a pivotal strategy for enhancing production workflows. By harnessing real-time data, manufacturers can identify bottlenecks and inefficiencies in their assembly lines. Advanced analytics tools allow for the meticulous tracking of various parameters, such as cycle times and quality metrics. This information helps in pinpointing specific areas where improvements can be made, from optimizing machine settings to refining employee workflows, ultimately streamlining operations and boosting productivity.

Moreover, integrating data analytics not only aids in enhancing efficiency but also significantly reduces lead times. Predictive analytics can forecast demand and guide inventory management, ensuring that the optimal amount of materials is available without delays. Additionally, by analyzing historical production data, companies can anticipate potential disruptions and implement proactive measures to mitigate risks. This data-driven approach ultimately leads to higher-quality outputs, aligning with consumer expectations while also contributing to cost savings in the long run.