WORLD electronics offers a complete line of electronic circuit board manufacturing and assembly services, as well as advanced manufacturing services. Our commitment to quality and service is second to no supplier.

Learn MoreOur team of engineers assists you in the development of new designs to optimize quality manufacturability (DFM) and testability, resulting in cost minimization and reduced product development time.

Learn MoreOur flexible manufacturing floor layout and highly trained staff allow for Quick Set-up and Tear Down of small volume prototype runs. This combination grants our customers the benefit of turning new designs quickly and accurately.

Learn MoreWORLD electronics is dedicated to quality. This quality is what underpins our commitment to thorough testing. Our engineers can develop a set of tests that ensure reliability and high performance in all products.

Learn MoreSupply chain management has crossed over from being a narrow management function to being a key operational function.

Learn MoreIn the fast-evolving landscape of electronics manufacturing, optimizing the board assembly process has become paramount for companies striving to enhance overall efficiency and meet growing market demands. According to a recent report from Research and Markets, the global printed circuit board (PCB) market is expected to reach $90 billion by 2025, underscoring the pivotal role that efficient board assembly plays in sustaining competitiveness in this sector. As technology progresses, manufacturers are challenged to reduce production times and costs while maintaining high quality and precision.

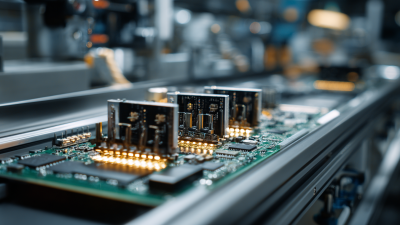

Moreover, a study by IPC, the Association Connecting Electronics Industries, highlights that organizations implementing streamlined board assembly processes can improve their operational efficiency by up to 30%. This remarkable potential for improvement drives the exploration of innovative techniques, automation, and best practices in board assembly. By embracing these changes, companies not only enhance their productivity but also significantly reduce the risk of defects, thereby better satisfying customer demands and boosting their market standing. As we look ahead towards 2025, understanding how to refine the board assembly process becomes crucial for any manufacturer seeking to thrive in an increasingly competitive environment.

To achieve maximum efficiency in board assembly, identifying key components is crucial. First, consider the use of advanced automation tools. Implementing robotic arms and automated pick-and-place systems can significantly reduce the time it takes to assemble boards. These systems not only enhance precision but also minimize human error, leading to higher quality outputs and faster turnaround times. Additionally, incorporating automated testing devices at various stages of assembly ensures that defects are identified early, thus reducing rework costs and ensuring a more streamlined assembly process.

Another essential component is the careful selection of materials and components. Using high-quality materials can enhance the performance and reliability of the final product, which is vital in today’s competitive market. Collaborating closely with suppliers to ensure timely delivery of components can prevent delays in the assembly line. Additionally, adopting lean manufacturing principles can help in identifying and eliminating waste in the assembly process, facilitating a smoother workflow. By focusing on these key components—automation, quality materials, and lean practices—organizations can optimize their board assembly process for unparalleled efficiency.

Streamlining the assembly line is crucial for boosting overall efficiency and productivity in board assembly processes. One effective technique to enhance workflow is the implementation of lean manufacturing principles. By identifying and eliminating waste in every stage of the assembly line, teams can focus on optimizing each task, reducing cycle times, and minimizing excess inventory. Utilizing tools such as value stream mapping can help visualize processes, spotlight bottlenecks, and highlight areas for improvement.

Another strategy is to invest in automation and advanced technologies. Integrating automated solutions, like robotic arms and smart conveyor belts, can significantly speed up repetitive tasks and improve precision in assembly. Furthermore, adopting real-time data analytics tools can provide insights into production metrics, allowing for quick adjustments and informed decision-making. Encouraging a culture of continuous improvement among team members fosters innovation and keeps the assembly line agile and responsive to changing demands. By prioritizing these techniques, organizations can expect to achieve a more efficient board assembly process, ultimately leading to higher quality products and enhanced customer satisfaction.

To optimize the board assembly process for maximum efficiency in 2025, leveraging automation tools is crucial. The integration of advanced technologies, particularly in areas like AI-driven automations and sensor technologies, can greatly enhance the speed and precision of assembly operations. These tools not only reduce human intervention but also streamline workflows, ensuring that assembly lines run smoothly with minimal downtime.

In addition, AI applications in manufacturing—such as real-time monitoring and predictive analytics—can transform traditional assembly methods. By implementing computer vision systems and work order management software, manufacturers can improve quality control and reduce defect rates significantly. Such innovations allow businesses to monitor production in real time, adapt to changes swiftly, and maintain high standards in output quality. As the manufacturing landscape evolves, the strategic adoption of these technologies will be essential for companies seeking to enhance their board assembly process and stay ahead of the competition.

This chart illustrates the efficiency percentage of different assembly process types in board assembly, highlighting how automation tools can significantly improve operational efficiency. Manual assembly shows lower efficiency, while fully automated processes provide optimal performance.

Quality control is a critical aspect of the board assembly process that directly impacts the overall efficiency and reliability of the final product. Implementing strict quality control measures at each stage of assembly helps to identify defects early, reducing the risk of expensive rework and delays. One effective practice is to establish standard operating procedures (SOPs) that outline the expected quality benchmarks for every step, from component placement to soldering and inspection. Regular training sessions for assembly staff on these SOPs can enhance their skills and familiarity with quality standards, fostering a culture of excellence.

Additionally, utilizing automated inspection technologies, such as Automated Optical Inspection (AOI) systems, can significantly enhance quality control efforts. These systems provide real-time feedback on the assembly process, allowing for immediate corrections before defects escalate. Integrating statistical process control (SPC) metrics further promotes ongoing improvements, as teams can analyze data trends to identify potential areas for process enhancement. By prioritizing these best practices, companies can ensure that their board assembly processes not only meet quality standards but also operate at maximum efficiency.

To optimize your board assembly process, investing in the training and development of your workforce is crucial. A well-trained team not only enhances efficiency but also improves the quality of the final product. By implementing structured training programs that focus on the technical skills required for board assembly, companies can ensure that their employees are equipped to handle various challenges and complexities. Regular workshops and hands-on training sessions can help workers become more proficient and confident in their roles.

In addition to technical skills, developing soft skills such as teamwork and communication is equally important. Board assembly often involves collaboration among different team members, and fostering an environment that encourages open communication can lead to improved problem-solving and innovation. By emphasizing a culture of continuous learning and support, organizations can empower their workforce to take ownership of their tasks, resulting in a more efficient assembly process and higher overall performance.